English ![]()

+86-17692703999

+86-17692703999 No. 6, West Side Auxiliary Road,

Sunshine Street, Linxi County, Xingtai

City, Hebei Province

Sunshine Street, Linxi County, Xingtai

City, Hebei Province

Views: 0 Author: Site Editor Publish Time: 2025-07-23 Origin: Site

A bushing is an important part in machines. It helps lower friction and stops parts from wearing out fast. There are different types of bushings. These include sleeve, flanged, spherical, and rubber bushings. Each type is made for a special job. Makers pick materials like bronze, steel, brass, plastic, rubber, and composites. They choose based on how the bushing will be used. In building machines, the right bushing helps machines last longer. It also makes them work better. The bushings market is worth over 8 billion dollars in 2024. This shows how important bushings are for big machines like excavators and loaders.

Bushings help lower friction and keep machine parts safe from damage. They make machines last longer and work better.

There are many types of bushings. These include sleeve, flanged, spherical, rubber, and custom bushings. Each type is made for a special job or load.

Bushings can be made from bronze, steel, brass, plastic, rubber, or composites. The material changes how bushings work in different places and uses.

Picking the right bushing depends on load, speed, environment, and how much care it needs. This helps bushings last longer and saves money.

Taking care of bushings and changing them on time keeps machines working well. It also lowers repairs and makes things safer in jobs like construction, cars, and mining.

Bushings are very important in machines. They help lower friction and support heavy things. They also help machines last longer. There are many types of bushings. Each type has a special job in factories and on building sites.

The main types are:

Sleeve bushings: These are round and help parts slide. They also hold up weight from the side.

Flanged bushings: These look like sleeve bushings but have a rim. The rim keeps them in place and makes them stable.

Spherical bushings: These let parts move at angles. They help when parts do not line up right.

Rubber bushings: These soak up shakes and bumps. They also make machines quieter.

Custom bushings: These are made for special jobs. They are used in big machines like those in mines or on building sites.

Some bushings are made for special uses. These include grooved bushings, thrust washers, carbon graphite bushings, and self-lubricating bushings. These bushings help machines work better and last longer in tough places.

Tip: Picking the right bushing helps machines work well. It also means you do not have to fix them as often.

Sleeve bushings are also called plain bushings. They are the most common kind in big machines. They help with side loads and let parts move smoothly.

Grooved bushings are a kind of sleeve bushing. They have grooves or holes to hold oil. This lowers friction and helps them last longer.

Some bushings are made from hard steel. These are strong and do not wear out fast. They are good for heavy work.

Machines like excavators and loaders use sleeve bushings in many places. These include pivot points, axles, steering joints, and hydraulic cylinders. Sleeve bushings keep these parts from wearing out too soon. They help machines work well.

Flanged bushings have a rim at one end. The rim stops them from moving sideways. It also keeps them in the right spot.

This shape lets flanged bushings hold both side and end loads. That is why they are used in loaders and excavators.

The rim makes the connection stronger. It also helps the bushing hold more weight, especially at hinges and joints.

Some flanged bushings have grooves. These grooves help oil spread and lower the need for repairs in big machines.

Spherical bushings have a ball-shaped inside. This lets them turn at angles.

They spread weight over a bigger area. This makes them strong and long-lasting.

Machines with moving joints, like excavators and cranes, use spherical bushings. These bushings help send power and stop parts from bending.

Spherical bushings are better than rubber bushings for heavy loads. They also keep joints steady.

Rubber bushings are stretchy and strong. They soak up shakes and bumps.

They act like cushions and keep parts apart. This makes machines quieter.

There are different shapes, like solid, hollow, flange, and sleeve. The shape changes how well they stop shaking.

Rubber bushings are used in engine mounts, suspension, and big machines. They protect parts and make machines more comfortable to use.

Some rubber bushings have grooves. These grooves help them stop shaking even better and last longer.

Custom bushings are made for special needs in mining, building, and factories.

Companies like Hebei Zhuoqun Machinery Parts Manufacturing Co., Ltd., Ltd. work with customers. They help pick the best materials and shapes for each job.

Custom bushings can be plain, flanged, spherical, tapered, split, self-lubricating, or composite.

They are made with care so they work well in tough places.

For example, some custom grooved bushings are made from strong metals. These last a long time and help mining machines work without stopping.

Type of Bushing | Functions | Typical Applications |

|---|---|---|

Sleeve | Radial load support, sliding motion | Pivot points, axles, hydraulic cylinders |

Flanged | Axial positioning, stability | Loader hinges, excavator joints |

Spherical | Angular rotation, misalignment compensation | Articulated joints, cranes |

Rubber | Vibration damping, noise reduction | Engine mounts, suspension systems |

Custom | Tailored functions, durability | Mining, construction, specialized machinery |

Note: Making bushings for special jobs helps machines work better. It also helps them last longer and break down less.

Picking the right material for bushings is very important. It affects how well they work, how long they last, and how much they cost. The most used materials for bushings are bronze, steel, brass, plastic, rubber, and composite materials. Each one has its own good points. Some work better in certain machines or places.

Bronze is a top choice for bushings in big machines. It is strong and lasts a long time. Bronze bushings can handle heavy loads and do not wear out fast. They also have low friction. This makes them great for building machines, cars, and boats.

Property | Value/Range | Notes |

|---|---|---|

Static Load Capacity | 150 N/mm² | Handles heavy shock loads |

Dynamic Load Capacity | 60 N/mm² | Standard CuSn12 bronze bushings |

Max Dynamic Load (Graphite Plugged) | 70 N/mm² | Self-lubricating variant |

Hardness | 75-95 HB | Varies by alloy and treatment |

Tensile Strength | >270 MPa | High strength |

Yield Strength | >150 MPa | |

Friction Coefficient (Dry) | 0.12 - 0.16 μ | For graphite plugged bushings |

Friction Coefficient (Oil) | 0.03 - 0.08 μ | For graphite plugged bushings |

Operating Temperature Range | -40°C to +400°C | Suitable for demanding environments |

Bronze bushings sometimes get special coatings like graphite spray. These coatings help them slide better and last longer. Heat treatments can make them even harder and less likely to bend. Bronze can take high heat and does not rust easily. This is why it is used in tough places.

Bronze bushings last longer and hold more weight than plastic ones. This makes them a smart pick for big machines.

Steel bushings are used a lot in heavy machines. There are hardened steel bushings and stainless steel bushings. Steel is very strong and can hold a lot of weight. These bushings are found in building machines, mining tools, and tools that need to be exact.

Steel bushings get stronger with heat treatments:

Carburizing puts more carbon on the outside to make it harder.

Quenching and tempering make it hard but not too brittle.

Nitriding adds nitrogen to make the surface even tougher.

Coatings like galvanizing and chrome plating help stop rust and lower friction. These changes make steel bushings good for heavy loads, high heat, and places where things might rust.

Steel bushings are best for machines like excavators and loaders.

Hardened steel bushings last longer at joints and pivot spots.

Stainless steel bushings work well in wet or chemical places.

Heat treatments and coatings help steel bushings last longer in factories.

Brass bushings are good because they do not rust and slide easily. Brass is made from copper and zinc. It does not rust, so it is used in boats and mines. Some types like CuAl10Ni and RG7 are even better at fighting rust and wear.

Brass bushings work well in salty water, chemicals, or outside.

Adding graphite to brass makes it even better at sliding and not rusting.

Grades like H59, H62, and H65 are picked for their strength.

Brass bushings are often used in pumps, valves, and boat parts. These places often get wet or have chemicals.

Plastic bushings are made from special plastics like nylon, PTFE, POM, and PEEK. They are light, slide well, and do not wear out fast. These bushings are best for fast-moving, light jobs where you do not want to do much upkeep.

Plastic bushings give:

Self-lubrication, so you do not need oil.

They do not rust and keep their shape.

They are quiet and help stop shaking.

Plastic bushings can move fast and still work well. They are used in cars, planes, and machines where weight and easy care matter.

Rubber bushings soak up shakes and noise. They act like soft pads between moving parts. They are used in engine mounts, car suspensions, and big machines to protect parts and make them smoother to use.

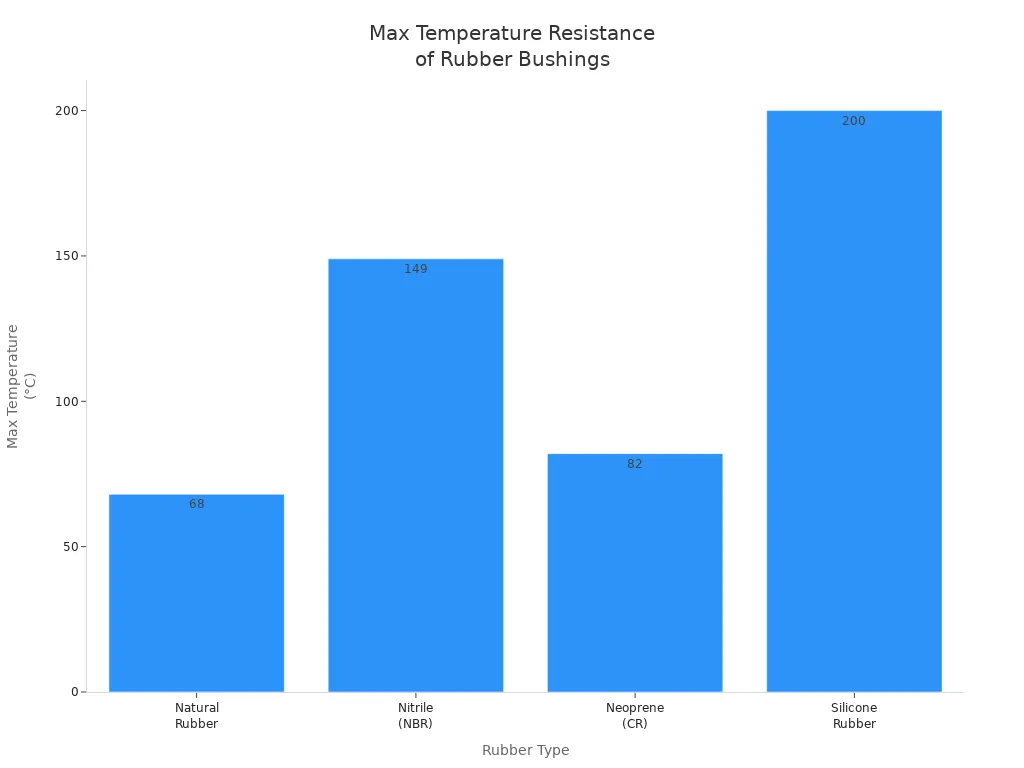

Rubber Type | Temperature Range | Chemical Resistance Highlights |

|---|---|---|

Natural Rubber | Up to 155°F (68°C) | Poor resistance to oil, gasoline, ozone, and sunlight; not for long-term chemical exposure |

Nitrile (NBR) | -65°F to 300°F (-54°C to 149°C) | Very good resistance to oil, gasoline, petroleum-based fluids; poor resistance to ozone and sunlight |

Neoprene (CR) | 10°F to 180°F (-12°C to 82°C) | Moderate resistance to oil and gasoline; good resistance to weather, ozone, and aging |

Silicone Rubber | Up to +200°C (392°F) or higher | Outstanding temperature stability; excellent resistance to ozone, UV, and moisture |

Rubber bushings can be made for special heat or chemical needs. Silicone rubber can take a lot of heat and does not get damaged by sunlight. This makes it good for outside or hot places.

Composite bushings are made from fibers, resins, and things like PTFE or graphite. These bushings slide well, hold heavy loads, and do not rust or get damaged by water or chemicals.

Composite bushings keep their shape even under heavy weight.

They help make machines quieter and stop shaking.

They are light, which helps machines work better.

They do not need oil, so they are easy to care for and better for the environment.

Composite bushings are used in planes, race cars, and places with high heat or lots of weight.

Companies like Hebei Zhuoqun Machinery Parts Manufacturing Co., Ltd., Ltd. can make bushings from special materials. They can change the size, coating, and how the bushing works to fit what the customer needs.

When picking bushings for big machines, you must know the load and speed. Bushings can hold different weights and move at different speeds. Not every bushing works for every job.

If the machine is heavy, use bushings made from bronze or steel.

If the machine moves very fast, bearings are better than bushings. Bushings can make more friction.

The material of the bushing changes how it handles stress and heat.

The right size and shape help stop friction and wear.

Lubrication helps bushings last longer, especially in hard places.

Bushings help moving parts and stop them from wearing out. In heavy jobs, bushings are strong and save money.

Where the machine works changes what bushing you need.

Factor | How It Affects Choice |

|---|---|

Load | Use strong bushings for heavy machines |

Temperature | Use metal bushings for hot places, plastic for warm |

Chemical Exposure | Use PTFE or composite bushings for chemicals |

Moisture/Corrosion | Use stainless steel or composites for wet places |

Noise Reduction | Use polymer or composite bushings for less noise |

Hebei Zhuoqun Machinery Parts Manufacturing Co., Ltd., Ltd. makes special bushings for different places. Their team helps pick the best materials and coatings for each job.

Taking care of bushings helps them last longer.

Check pins and bushings before each season starts.

Turn or change bushings every 2,000 hours, or as needed.

Add oil or grease when the maker says to.

Look for signs like track pitching to know when to fix things.

Self-lubricating bushings need less care. This saves time and work.

Cost is important when picking bushings for big jobs.

Think about all costs, not just the price to buy.

Good bushings mean fewer repairs and less time stopped.

Self-lubricating bushings cost less to take care of.

Lighter composite bushings are cheaper to ship and put in.

It is smart to think of bushings as something that lasts a long time.Hebei Zhuoqun Machinery Parts Manufacturing Co., Ltd., Ltd. can make bushings that fit just right. This helps you get more benefits and spend less.

Tip: The right bushings help machines work better, cost less, and last longer.

Bushings are very important in construction machines. Big machines like excavators, loaders, and cranes use bushings at pivot points. Bushings help parts move smoothly and stop them from wearing out fast. C45 hardened steel bushings are used a lot in these machines. They hold up moving parts and can take heavy weight. They do not wear out quickly because they are very hard. Lubrication and regular care help bushings last longer, even in tough places. Construction machines need bushings to work well and cost less to fix.

Main ways bushings are used in construction machines:

Pivot points on excavator booms

Joints on loaders and cranes

Connections for hydraulic cylinders

Picking the right bushing helps construction machines work longer and better.

Bushings are needed in car suspensions and steering systems. Good bushings with PTFE linings lower friction. This lets parts move exactly right without needing extra oil. It makes rides smoother, lowers shaking, and helps cars stay steady. Bushings also soak up bumps and noise, so rides are safer and more comfortable. If bushings wear out, cars may handle badly, tires may wear unevenly, and strange noises can happen. Checking and changing bushings on time keeps cars safe and working well.

Industrial machines use bushings to lower friction and noise between moving parts. Strong bushings like cast bronze or polyurethane can hold heavy loads and stop parts from breaking early. These bushings act like shields, soaking up shakes and helping other parts last longer. Picking and putting in the right bushings helps stop surprise breakdowns. Machines like presses, automation systems, and material movers need bushings for smooth work and less upkeep.

Main benefits of bushings in industrial machines:

Less shaking and noise

Longer life for equipment

Fewer repairs needed

Mining machines work in hard places, so bushings must be tough and last long. Bushings help stop wear on joints that move a lot. Self-lubricating bushings are used in mining because they need less care and keep machines safe. Taking care of bushings helps tracks stay straight and stops safety problems. Changing bushings before they break helps avoid long stops and keeps mining running well.

Using bushings in mining machines helps equipment last longer, keeps workers safe, and lowers repair costs.

Bushings are used all over the world in many industries. Companies in Asia Pacific, North America, Europe, and new markets use bushings in construction, cars, factories, and mining. Makers like Hebei Zhuoqun Machinery Parts Manufacturing Co., Ltd. create special bushings for each job, helping customers everywhere.

Picking the right bushing and material helps machines work well in building and mining. Some important steps are:

Ask makers for help early.

Think about weight, speed, and where the machine works.

Get advice to make sure the bushing fits.

Customization Aspect | Reliability Benefit |

|---|---|

Specialized Materials | Lasts longer in tough places |

Self-Lubricating Features | Less rubbing and longer use |

Advanced Manufacturing | More exact parts and fewer stops |

Bushings made for your needs and expert help make machines last longer and work better.

A bushing helps moving parts slide easily. It holds up heavy parts and stops them from wearing out fast. Construction machines use bushings to make equipment last longer and work better.

Tip: Good bushings help save money on repairs and keep machines working longer.

Steel and bronze bushings are great for tough places. They do not wear out fast and can handle heat and rust. Composite bushings also work well when things get really rough.

Material | Durability | Corrosion Resistance |

|---|---|---|

Steel | High | Moderate |

Bronze | High | High |

Composite | High | High |

People should check bushings every 2,000 hours or at the start of each season. How often you change them depends on how much they wear and the job they do. Checking bushings often helps stop surprise problems.

Companies like Hebei Zhuoqun Machinery Parts Manufacturing Co., Ltd., Ltd. can make special bushings. They use drawings, samples, or what the customer wants. Custom bushings fit machines better and help them work their best.

You might hear more noise or feel shaking. Joints may feel loose or move unevenly. Worn bushings can break machines. Finding and changing them early keeps machines working well.